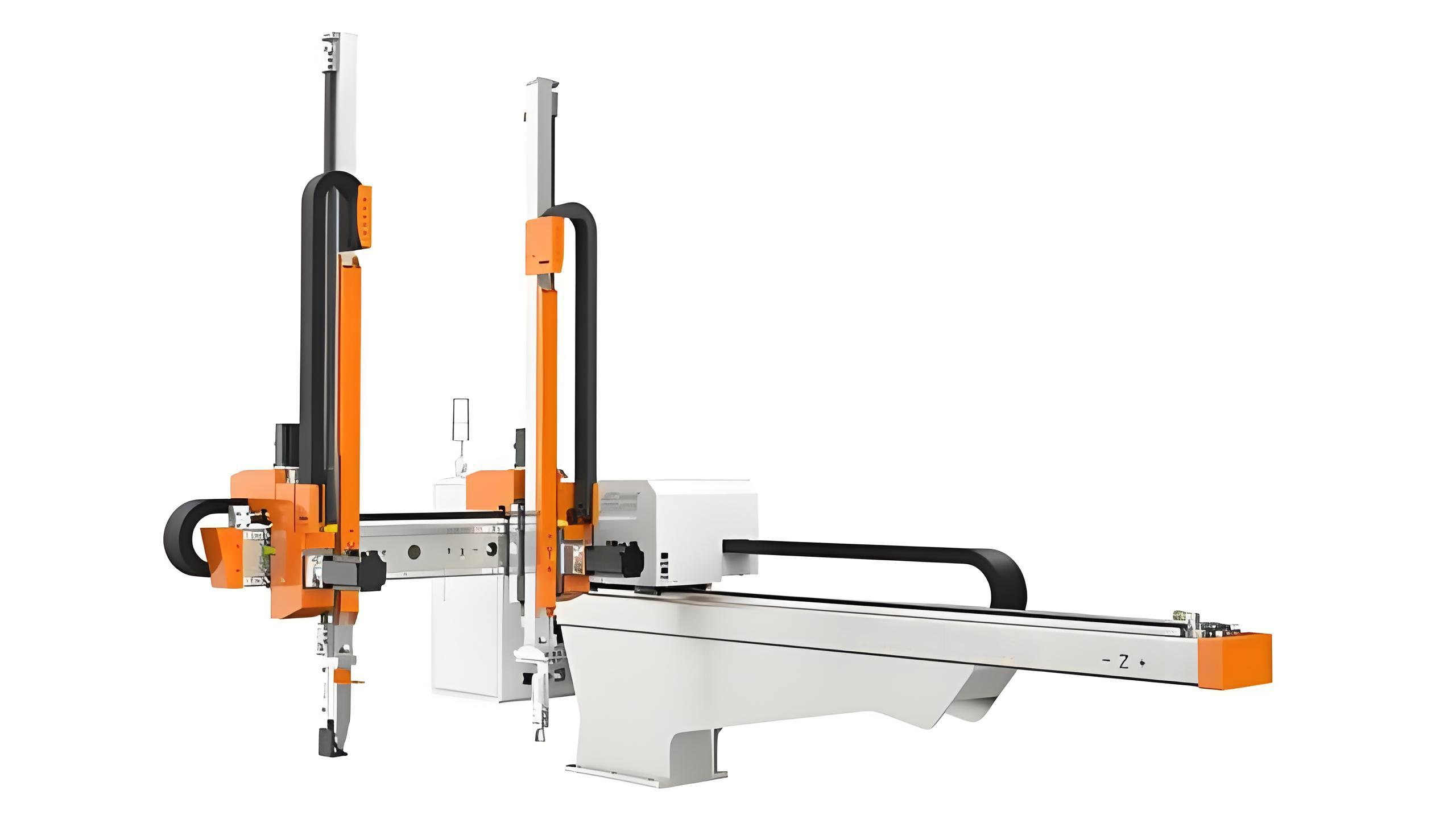

The integrated solution for the drive and control of the Motong transmission truss robotic arm adopts Motong transmission, which is specifically developed for the robotics industry

MSC8 series robotic arm dedicated drive control integrated system, integrating M810 series bus type multi axis modular servo drive with M8

Series bus type controller, equipped with M8 series dedicated teaching pendant and MT2 series high-performance servo motor, forming a complete drive system

Dynamic and control closed loop.

High speed and precise control system, multi axis synchronous communication, synchronization error less than 10ns, ensuring high-speed operation of the truss manipulator

Can still maintain stable operational accuracy and improve the overall efficiency of the production line; Integrated design reduces the complexity of equipment maintenance

Sex, while saving 50% installation space and 50% wiring harness costs; Multiple interrelated security measures ensure the safety of the loading and unloading process

The safety of molds, fixtures, and workpieces effectively prevents mechanical collisions and personnel injuries; Flexible expandable servo axis count

(1-12 axes, single axis power 50w-4kw) and EtherCAT remote IO module can meet the customized needs of different production lines.

At present, the integrated solution of mechanical arm drive and control for Motong transmission truss has been provided to enterprises in injection molding, new energy, 3C and other industries

A new development opportunity has arrived, and through the application of this solution, the production efficiency of various enterprises has significantly improved and operating costs have significantly decreased

Low, thus occupying a more advantageous position in market competition.

Scheme introduction

Integrated solution for truss manipulator drive and control