MSC8 series

manipulator dedicated drive control integrated system

manipulator dedicated drive control integrated system

Drive and control integration, high integration, excellent performance and convenient debugging

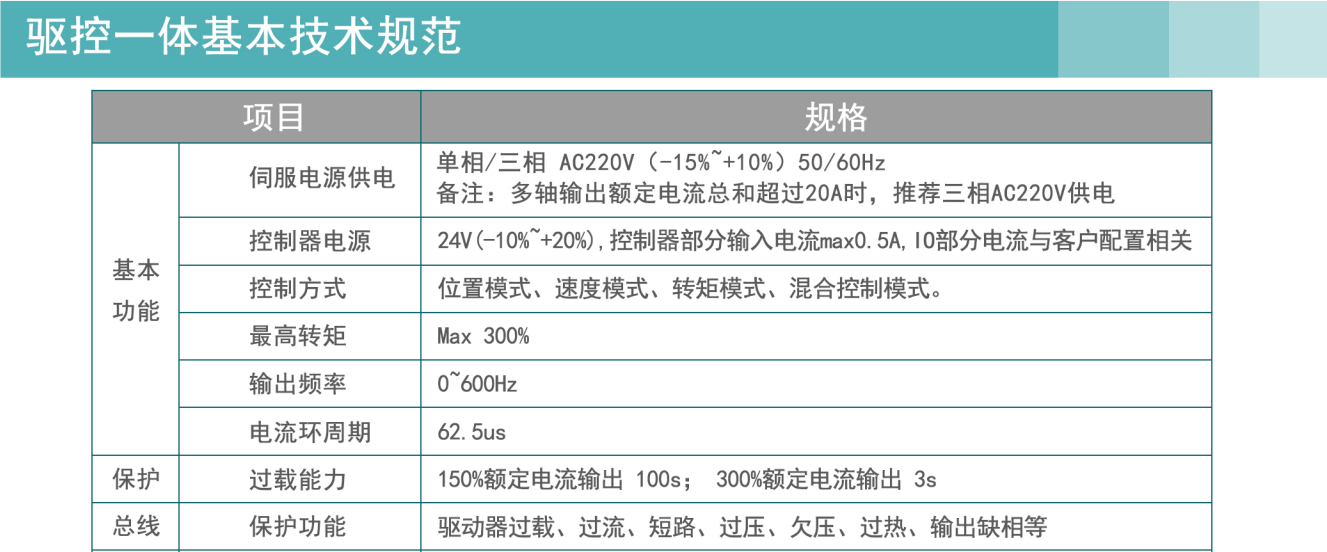

MSC8 series manipulator dedicated drive and control integrated product is a multi-axis modular drive and control integrated product launched for various loading and unloading and stacking application scenarios. This product is composed of M810 series bus-type multi-axis modular servo driver and M8 series bus-type controller, matched with M8 series dedicated teaching device and MT2 series high-performance servo motor, widely used in injection molding machines, punches, lathes, carving machines, packaging, 3C, new energy And other non-standard automation fields.

MSC8 series drive and control integrated system can effectively solve the industry pain points of drive and control separation, small data throughput, cumbersome setting of conventional pulse servo, pulse loss, weak anti-interference ability, low efficiency of batch assembly, complex maintenance, weak performance, high failure points, etc., greatly improve the assembly efficiency, shorten the commissioning cycle, and reduce the cost of electrical solutions. This series of products can flexibly expand the number of servo shafts (1~12 shafts, single shaft power 50w~4kW), have MES interface, modular assembly for easy maintenance, multiple process packages, field programmable, have multiple well line (subroutine) threads, and a single machine can complete a variety of workstation functions, directly control the conveyor belt, silo, etc., without external PLC.